Why Short-Run Package Printing is the Secret to Growing Your Business in 2022

Early adopters of short-run package printing practices have one thing in common: they are all experiencing an increase in post-printing, overprinting, and short-run capabilities, and ultimately, a greater bottom line. In this article, we will explore the current state of the packaging market and how the implementation of short-run package printing solutions is guaranteed to grow your business in 2022 and beyond.

- Direct-to-Package Printing and Short-Runs

- State of the Packaging Market

- Demand Driver

- Megatrends Influencing Package Design

- Opportunities in Commercial Printing

- Power of the T3-OPX Direct-to-Package Printer

Direct-to-Package Printing and Short-Runs

Whether you’re looking to print directly onto cartons, products, gift bags, paper bags, shopping bags, or others, chances are good that you do not require thousands of each at a time. And if you’re like most businesses, you likely do not have the storage space to accommodate thousands of units of each.

Traditionally, many key business decisions were influenced by the required print run sizes of third-party printers and the lack of storage available for overruns. Allowing decisions such as which products and services to offer, when and how brand messaging is displayed and updated, product size offerings, and more to be dictated by something as avoidable as a required print run size is simply not good business practice.

Customers often approach us saying if only they had the flexibility to customize and print directly onto a variety of materials, or product sizes, or run sizes, then they could expand their product and service offerings to grow their company exponentially. The thing is, direct-to-package printing and short-runs are no longer mutually exclusive items. It’s no longer a one or the other decision. Today’s technologies empower businesses and commercial printers alike to print the quantity of their choosing, directly onto a variety of packaging materials – cardboard, paperboard, boxes, paper bags, wood, envelopes, gift bags, and more. If you dream it, you can likely print on it these days – in as few as one unit at a time.

The State of the Packaging Market

To understand why package printing decisions are having such an impact on the business overall, we need to take a closer at the current state of the packaging market and the trends that are driving it.

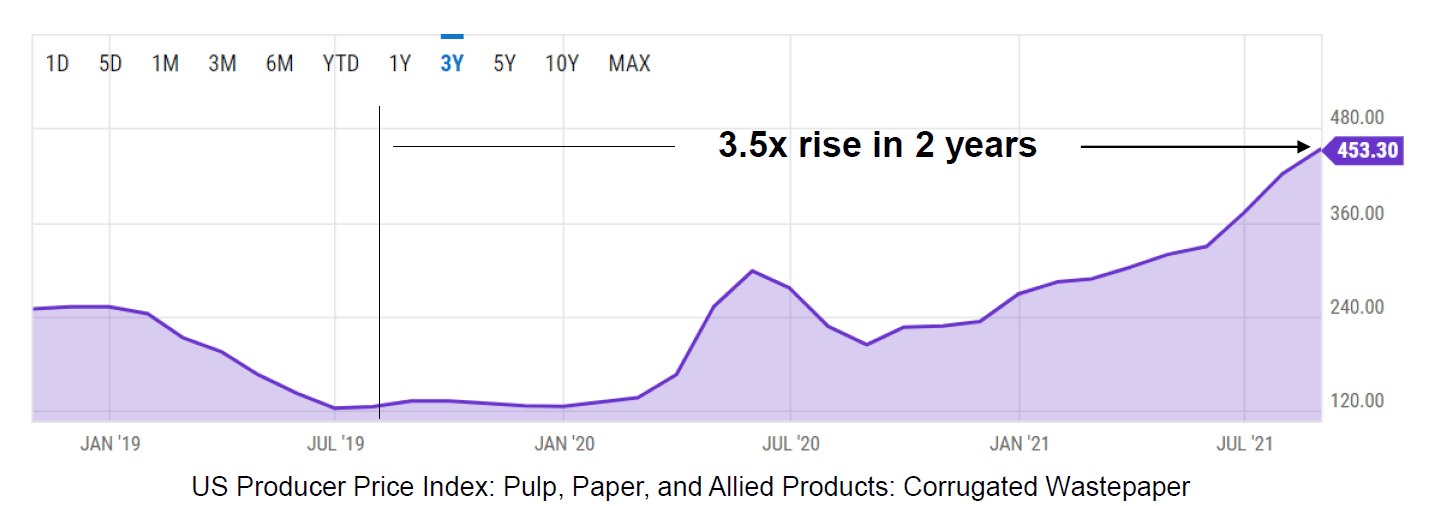

Currently, there is a record surge in demand for packaging, especially paper-based packaging. Basic economics tells us that price is a function of supply and demand. So what happens when there is a record surge in demand for packaging, but not enough supply in the market? The result is a steep rise in price, of course. In fact, the price index has increased by 3.5 times from two years ago. According to the US Producer’s Price Index for Pulp, Paper, and Allied Products, an upsurge in demand began at the beginning of 2020, at about the same time the Coronavirus pandemic began causing dramatic changes to our lives and economy.

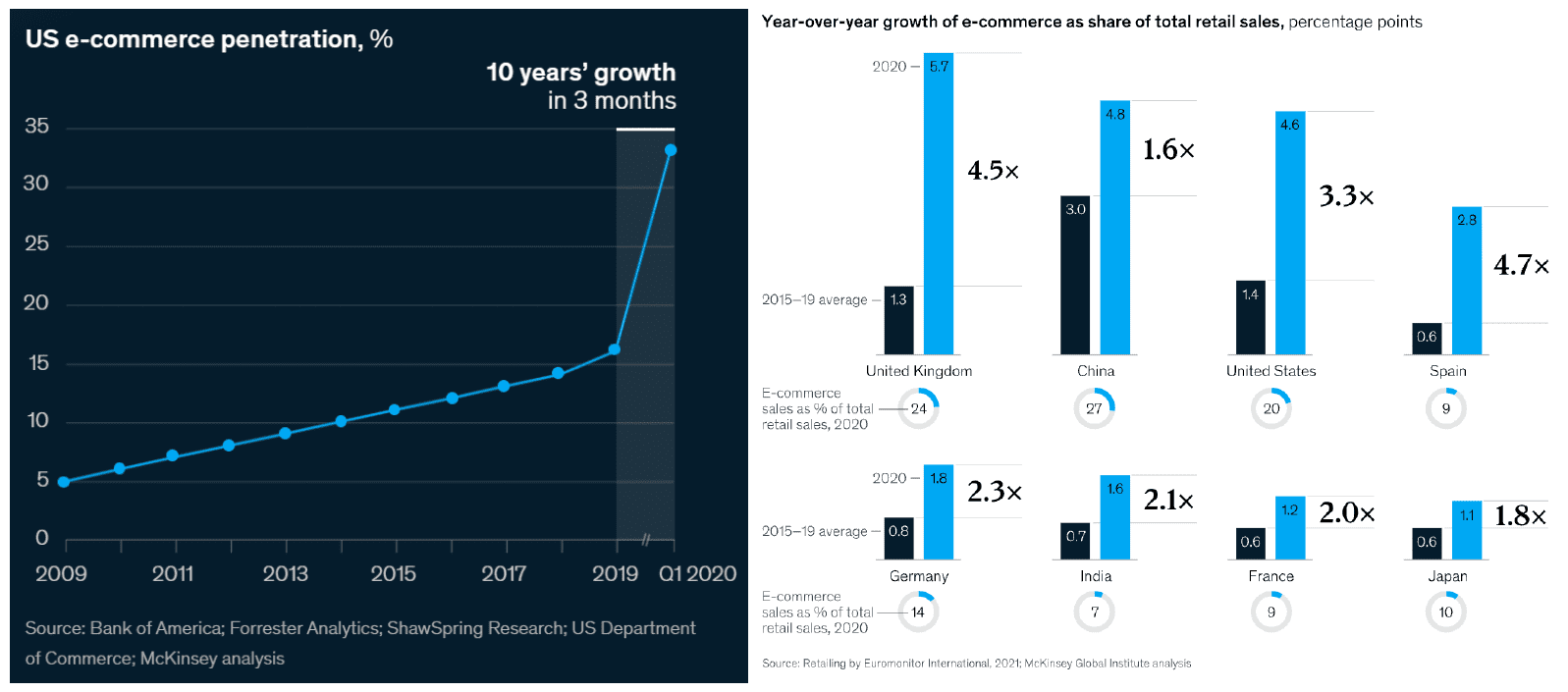

You might be wondering, why would a pandemic cause a rise in packaging demand? It was not the pandemic itself, it was the effect it had on all us consumers. With mandated lockdowns keeping us homebound, we began relying on e-commerce and delivery services to fulfill most of our needs. The eCommerce landscape itself adapted as well, creating a fusion of online and offline experiences such as BOPIS (Buy Online Pick-up In-Store), and curbside pick-up, and same-day delivery options. Suddenly, items that never required secondary packaging with additional transport protection now relied on these materials.

The exponential growth of eCommerce spurred by the pandemic had led to a sharp increase in demand as well as for packaging materials. With no end to the pandemic in sight, the future of retail remains murky, and eCommerce continues to rule the landscape. This has forced manufacturers and shippers to rethink packaging design in order to overcome supply-demand challenges and has also provided an opportunity to consider the top megatrends in the packaging industry and respond to them.

Top Megatrends are Influencing Packaging Redesigns

As we discussed in the previous section, demand for secondary packaging materials has driven many companies and shippers to rethink packaging designs over the past year or so. At the same time, the packaging industry has an eye on the major megatrends shaping the industry and finding solutions to respond accordingly.

Megatrends are transformative forces that can have the power to change the trajectory of an industry by shifting the priorities of societies, driving innovation, and redefining business models. The top three megatrends may not come as a surprise to you if you are an informed consumer, but the challenges they pose can cause pretty serious headaches among those responsible for finding solutions. Let’s dive in to each megatrend.

Megatrend #1: Sustainability

Sustainability and concern for the environment have been trending since before the pandemic, but seem to be influencing consumer behavior now even more than ever. Consider this stat from Trivium Packaging’s 2021 Buying Green Report: 73% of consumers are willing to pay more for eco-friendly packaging. Solutions for key sustainability features like reusability, environmental-friendly design, and recyclability are more important than ever. Consumers are making purchasing decisions based on brand alignment with their own values, and for many consumers, environmental responsibility is a core value. Brands are tasked with aligning themselves on every level, down to their packaging, with this value.

Megatrend #2: Brand Experience

The percentage of consumers that say packaging impacts their satisfaction with a purchased product increased by 9 points from 2019 to 2020, according to Westrock’s annual Pulse Packaging Survey. It is, therefore, no wonder that sustainability is a megatrend. In fact, according to the survey’s 2020 results, consumers said the following key sustainability features impact their trust and satisfaction with a brand: Easily reused materials (65%); Environmentally friendly design (68%); Easily recycled (68%).

Megatrend #3: Supply Chain Agility

The pandemic can be credited with many disruptions, including the unveiling of an inflexible supply chain. An agile, responsive supply chain is a coveted core competency, and we are going to see companies making significant investments in these solutions. The microtrends involved in supply chain agility include:

- Ecommerce friendly

- Cost-Effective

- Rapidly Adaptable

- Digitalization Ready

Evolving Ship-Ready Package Concepts for Today’s Landscape

In review, the top three megatrends currently influencing packaging redesign are 1. Sustainability; 2. Brand Experience; 3. Supply Chain Agility. As manufacturers and shippers adapt their strategies and rethink their approach to packaging, package designers have the challenging task of assimilating these megatrends to produce optimized designs to satisfy today’s landscape with ship-ready concepts.

Ship-ready packaging is packaging developed for efficient distribution from point A to point B. While traditionally the typical retail journey was from crate to shelf, in today’s eCommerce landscape the journey is more often from manufacturer to consumer, mandating a much different set of logistics and packaging requirements, including both primary and secondary packaging.

In a report titled, “Beyond COVID-19: The Next Normal for Packaging Design”, McKinsey explored some different types of boxes, cartons, cases, and envelopes that could be “ship-ready with minimal added transport and protective packaging”:

- Protection

- Tamper-proof

- Rapid fill

- Return

- Optimized for eCommerce

- Ship-ready

- Unboxing

- Track and trace

Ship-ready bags, boxes, cartons, and mailers tend to have a great deal of variability (ie type, shape, size, thickness, weight, quantity, etc.) but what they typically have in common is their composition from natural wood fibers, ensuring recyclability.

Opportunities in Commercial Printing

Now that we have reviewed the current climate of the packaging industry, and the emerging trends and their influencers, let’s take a look at what it means for printers and how you can grow your business with the right capabilities.

We know at this point that small and medium brands have more specific needs than has traditionally been the case. We know now what packaging decisions they are making and why, so the question becomes, how can you fulfill these needs and turn them around in short-run quantities? Every company will be different, but this is a list of the requirements we most often hear that small and medium brands and eCommerce retailers are looking for in a commercial printer:

- Must be able to post-print on a wide variety of package types

- Printing should not be preceded by any coatings or pre-treatments of any kind, as this increases cost and complexity

- Full-color printing capabilities

- Low or no minimum order quantities

- Short turnaround times

This is a pivotal moment in time where print service providers have an opportunity to be truly competitive, with the right approach. Consumers know what they want, and brands are ready to adapt and deliver. But businesses need to partner with print service providers that can support these needs. What it boils down to is businesses are using various package types and substrates, printed with varying messaging and in sporadic quantities, and they are needed on-demand. We’re constantly told that companies are looking for print partners can deliver the following:

- One direct-to-package solution for a wide variety of paper-based package types

- Digital inkjet (CMYK) that supports full-color short runs without plates

- Industrial grade build and reliability

- Economical and affordable for smaller print shops

To meet these demands, printers must invest in one single solution to print directly on a wide variety of paper-based package types, while also fulfilling the requirement for short runs in full color. Printers who can deliver on only one of these characteristics alone are being left in the dust while innovative printers are quickly adopting technologies that allow for specialized requests to be fulfilled, changing the expectations of their customers for the long term.

The Power of the TrojanLabel T3-OPX Direct-to-Package Printer

AstroNova has a long-standing record as an innovator in the print technology space and quickly sought to find a solution to meet the needs of today’s unprecedented times. We knew whatever shape the solution took, it must be built with industrial-grade quality for longevity and reliability, and it must be affordable for smaller print shops to acquire and operate with excellent print economics. We collaborated with HP Specialty Printing & Technology Solutions (SPTS) to bring the TrojanLabel T3-OPX to the market.

The TrojanLabel T3-OPX is a direct-to-package printing solution that was launched back in September 2019, prior to the changes brought about by the pandemic, with commercial shipments beginning in January 2020. Since then, the product has been installed across 5 continents and has proven instrumental in answering the demands we began to see in early January 2020.

Outstanding capabilities of the T3-OPX direct-to-package printer include:

- Flexibility to customize and print directly onto a variety of materials like postcards, boxes, paper bags, wooden planks, or thicker objects like blister envelopes, folded ship-ready boxes, and more

- Late-stage customization and package and design versatility

- High-quality, full-color printing directly onto materials with ink-receptive surfaces

- Automated product handling and printing process for greater efficiency and profitability

- Pigmented inks provide superior durability, optimized water resistance, lightfastness, and scratch resistance

- Unique, self-calibrating, adjustable product height to ensure optimal print quality while providing fast product changeovers

Technical features of the T3-OPX direct-to-package printer include:

- User-friendly, intuitive interface and built-in job library allow for easy operation and recall of product configuration parameters TrojanControl Software provides full local control plus a built-in cost calculator for easy job pricing and analysis

- Built-in remote diagnostics capability allows for remote status and diagnostics, minimizing production downtime

- Product grade designed for the rigors of 24/7 production

- Automatic heigh calibration for rapid changeovers and accurate print height for substrate thicknesses ranging from 0-4” (0-100mm)

- Economical CMYK ink cartridges provide outstanding print quality and vibrant, durable direct-to-package printing

- High-speed printing and product transport – variable up to 19 ips, delivers the optimal balance of print quality and productivity

- Feeder table and adjustable media guides enable easy integration with a variety of automatic feeder options with conveyor table

Conclusion

In conclusion, let’s do a quick review of five key takeaways:

- We’re experiencing exponential growth in packaging demand due to significant changes in the retail landscape, most notably due to an increase in the adoption of eCommerce by everyday consumers. While demand is up, supply is low.

- This demand has triggered a redesign of consumer packaging that must conform to the key megatrends of sustainability, brand experience, and supply chain agility.

- This packaging redesign is resulting in an opportunity for commercial printers and print service providers to expand their print offering by adding short-run printing capabilities on sustainable substrates like bags, boxes, cartons, and wood panels.

- Digital printing solutions like the TrojanLabel T3-OPX direct-to-package printer offer a valuable opportunity for printers to expand capabilities in this growing market in an affordable manner.